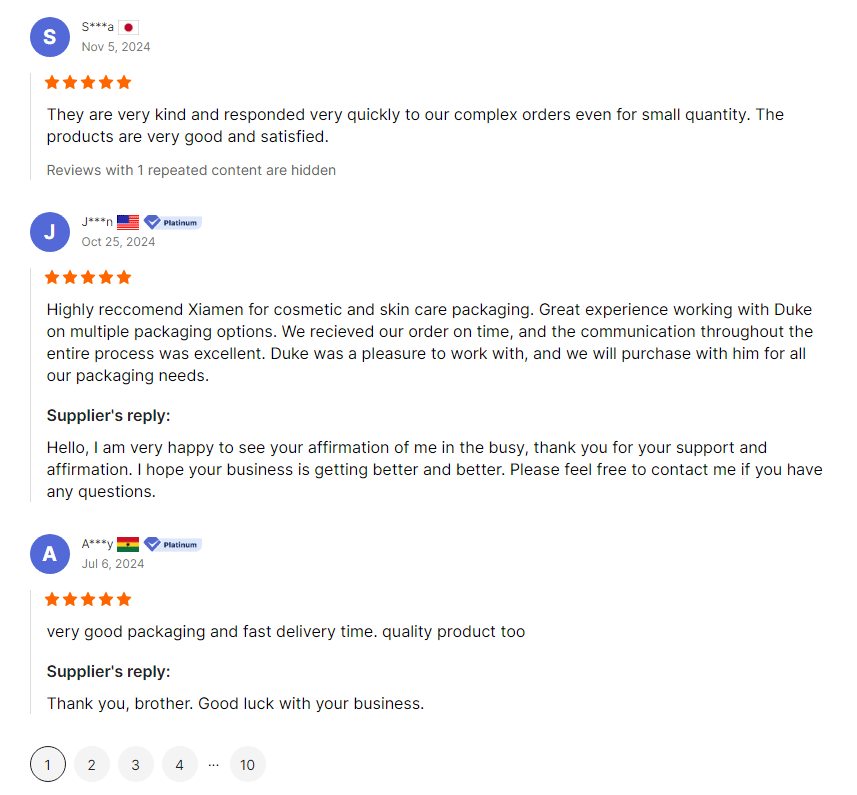

Reagent Bottle

The wide-mouth reagent bottle can hold pills or liquids.Generally, they come in colors such as Amber/Clear. We can also customize the color

according to your requirements.

| Name | Reagent Bottles |

|---|---|

| Capacity | 30ml/60ml/125ml/250ml/500ml/1000ml |

| Color | Amber/Clear/Custom |

| LOGO | Can customize |

| Industrial Use | Pharmaceutical |

| Material | Soda-lime Glass |

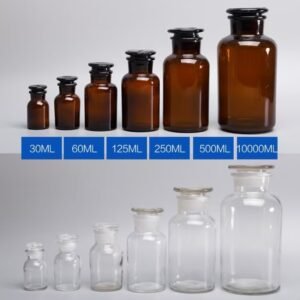

| Surface printing | Screen Printing, Hot Stamping, Label, frosted, etc |

Detailed Product information

-

Glass wide-mouth reagent bottles are essential laboratory containers designed for storing and handling various chemical substances. Typically manufactured from glass these bottles exhibit exceptional thermal shock resistance and chemical inertness, making them suitable for acids, alkalis, and organic solvents. The wide mouth design facilitates easy filling, pouring, and cleaning, while the standardized neck finish ensures compatibility with common laboratory closures like screw caps, ground glass stoppers, or PTFE-lined lids. Modern production techniques enable precise control over wall thickness and dimensional tolerances, with capacities ranging from 30ml to 1 liters. Quality control measures include rigorous testing for thermal durability (able to withstand temperature differentials exceeding 120°C) and chemical resistance (passing USP/EP hydrolytic class tests). Many bottles feature volumetric graduation marks and space-efficient square designs for improved storage. Recent advancements incorporate laser-etched permanent labeling areas and color-coding options for enhanced sample identification. Despite the growing popularity of plastic alternatives, glass remains preferred for high-purity applications due to its non-leaching properties and superior barrier characteristics against gas permeation.

-

The evolution of glass reagent bottles reflects changing laboratory needs and sustainability concerns. Manufacturers now employ advanced glass formulations with reduced alkali content to minimize surface interactions with sensitive reagents. Amber-colored variants provide UV protection for light-sensitive compounds, while specialized coatings can improve chemical resistance for hydrofluoric acid applications. The industry has made significant progress in lightweighting – modern bottles weigh 25-30% less than traditional designs while maintaining mechanical strength through optimized stress distribution. Environmental considerations drive the use of recycled cullet (up to 90% in some production lines) and energy-efficient melting technologies. Smart packaging integrations are emerging, including bottles with RFID tags for inventory management and QR code areas linking to digital safety data sheets. Cleaning and sterilization processes have been streamlined through improved surface treatments that reduce residue adhesion. Future developments may include self-cleaning photocatalytic glass surfaces and hybrid designs combining glass chemical resistance with plastic impact resistance. These innovations ensure glass reagent bottles remain indispensable in research, pharmaceutical, and industrial laboratories where material purity and long-term storage stability are paramount.

1-Product Specification

- Soda-lime glass in flint or amber/clear color

- Full automatic inspection system and independent lab analysis

- Shrink wrapped and strong corrugated carton or pallet

- Tablet / liquids

2-Product Specification

3-Processing & Production

4-Packing photo

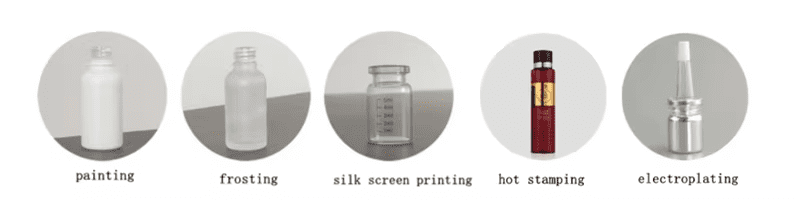

5-Real customer evaluation